What is the VTG Turbo?

Presented in 2006, Porsche 911 Turbo was the world’s first car to feature a turbocharged petrol engine with VTG technology. But what is the VTG turbo technology?

What is the VTG Turbo?

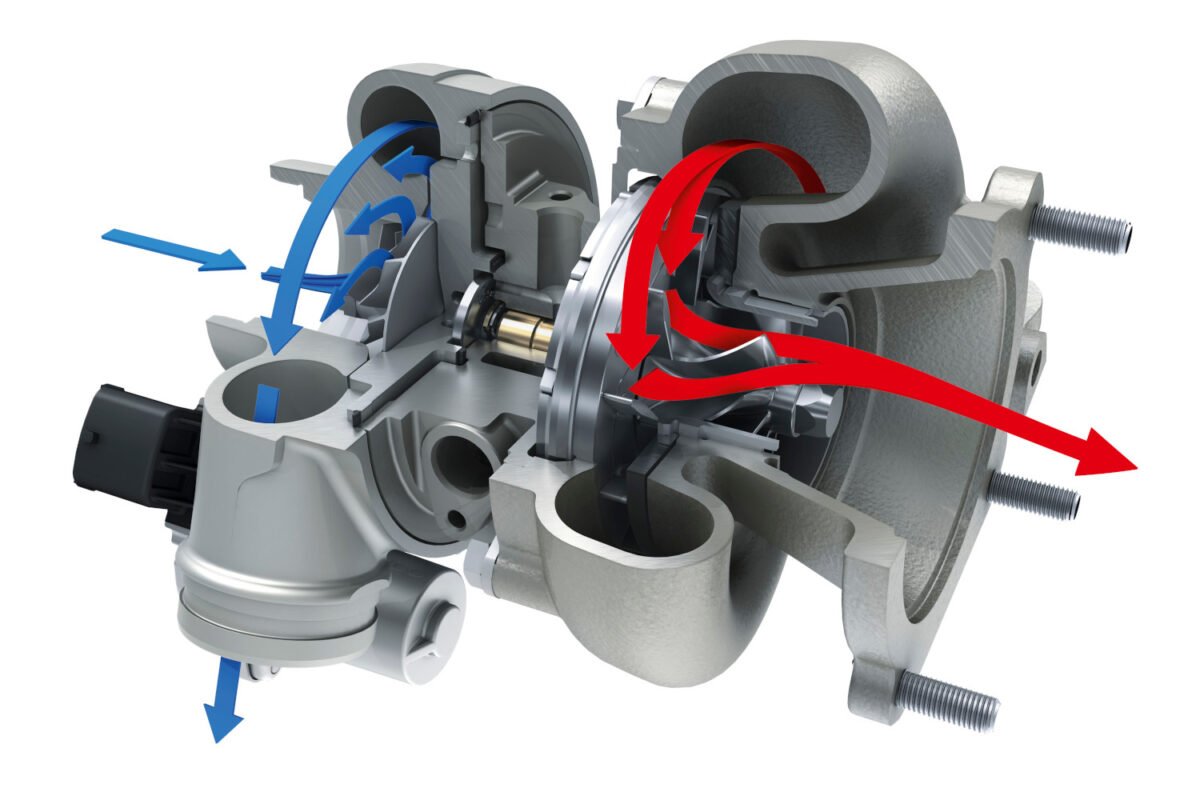

The letters VTG is the acronym for variable turbine geometry. The core features of the VTG system are the variable turbine blades guiding the flow of exhaust gas from the engine in exactly the direction required on to the turbine wheel of the exhaust gas turbocharger.

This technology makes it possible to deliver very good response and high torque at low engine speeds, and superior output and high performance at high speeds. Also the high level of torque is maintained consistently throughout a much wider speed range. So VTG Turbo makes it possible to enjoy the benefits of a small and large exhaust gas turbocharger all in one.

How Variable Turbine Geometry Works

Variable turbine geometry uses guide blades to simulate the cross-section of a turbocharger always optimised in size. At low engine speeds, the blades angle to form small air-flow openings. The exhaust gas flowing through the smaller cross-section accelerates accordingly and hit the turbine wheel with a high energy level. This blade angle is maintained until the system has built up the required boost pressure.

As exhaust gas flow continues to increase as a function of higher engine speed, the VTG guide blades open up and adjust the boost pressure accordingly. The electronic management and the electrically driven control mechanism are set up to give the blades an adjustment period from “open” to “closed” of approximately 100 milliseconds. The variable turbine geometry of the turbocharger can handle even the highest possible exhaust gas flow, so there is no need for a bypass valve.

World’s First

Before Porsche presented the 911 turbo, the variable turbine geometry had been used only with diesel engines because of the thermal reasons. For example, exhaust gas temperatures at the point leading into the turbine on a diesel engine are between 700 and 800 °C. The exhaust gas on Porsche’s turbocharged power units, has a temperature of 1000 °C.

Porsche solved this problem in close cooperation with Borg Warner Turbo Systems by using high temperature-resistant materials from space technology wherever required. Porsche’s engineers also developed a two-stage oil cooling system including a follow-up pump, as well as a water cooling system for the bearing housing, to help reduce the high temperatures.

Image by Porsche

- 2001 Porsche 911 Turbo Coupe (996) SpecsHere are the technical specifications of the 2001 Porsche 911 Turbo Coupe. Specs of the EU model

- Black 1957 Porsche 356 A 1600 Super SpeedsterHow cool is this black 1957 Porsche 356 A 1600 Super Speedster? It is in spectacular condition as a result of a comprehensive restoration completed in 2013 by RUF

- Peek Inside – 2025 Porsche 911 GT3 InteriorLet's peek inside the 2025 Porsche 911 GT3. For the first time, the GT3 is available with the Weissach Package

- Porsche 911 Third Generation (1988-1994)The third generation Porsche 911 is known internally as the type 964. It was manufactured between 1988 and 1994

- Porsche 992.2 Plays YoutubeThere is no shortage of entertainment in your sports car as YouTube is now included as standard in all new Porsche 911 models that support in-car video